https://www.ascendtechs.com/guangzhou-ascend-micro-dispensing-pumps-empower.html

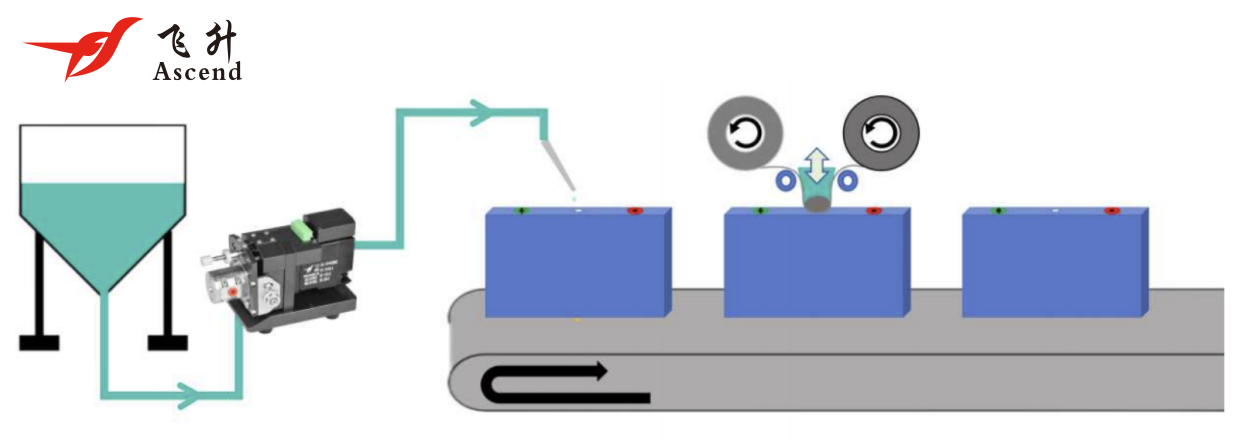

In the prismatic battery manufacturing industry, the cleanliness of the liquid injection nozzle is one of the key links determining battery performance, which directly affects the welding process. The micro-dispensing pump is suitable for the DMC cleaning (wiping machine) scenario of the liquid injection nozzle, and can accurately control the micro-output of DMC cleaning fluid according to the production process requirements. Its stable dispensing performance can avoid the problems of cleaning fluid waste or incomplete cleaning, which not only ensures the cleaning effect of the liquid injection nozzle but also maintains the continuity of the production process, providing important support for the stable mass production of prismatic batteries.

Meanwhile, in the grinding wheel application scenarios in the mechanical processing field, this micro-dispensing pump also performs excellently. During the high-speed operation of the grinding wheel, it is prone to generate high temperatures due to friction, leading to increased wear and shortened service life, and uniform dripping of lubricating oil is the key to alleviating this problem. The micro-dispensing pump can achieve precise quantitative dripping of lubricating oil, allowing the lubricating oil to act appropriately on the contact area between the grinding wheel and the workpiece. It effectively reduces the friction coefficient and carries away heat, which not only reduces the wear and consumption of the grinding wheel but also improves the surface precision of the processed workpiece, providing double guarantee for the high efficiency and high quality of mechanical processing.

As a precision device specially designed for industrial scenarios, the optimization of the micro-dispensing pump in structure and material endows it with practical value far exceeding that of similar products.

1.The equipment adopts an integrated design that highly integrates core components such as drive and control. It not only simplifies external connections and operation processes but also makes the control logic clear and easy to understand. Operators can accurately adjust parameters such as dispensing volume and dispensing frequency through simple operations without complex training, quickly adapting to the needs of different production conditions.

2.The integrated design endows the equipment with the significant advantage of maintenance-free operation, reducing downtime caused by component disassembly and replacement, lowering maintenance costs and labor input during equipment operation, and making the production process smoother and more hassle-free.

3.The core parts in contact with liquids are exquisitely made of high-quality ceramics and 316 stainless steel for the equipment. Ceramic materials possess extremely high hardness and chemical stability, while 316 stainless steel is renowned for its excellent corrosion resistance. The combined application of these two materials enables the equipment to easily cope with different types of liquid media such as DMC cleaning fluid and various lubricating oils, effectively resisting corrosion, wear and other issues, and greatly extending the service life of the equipment. For enterprises engaged in long-term continuous production, this feature not only reduces the frequency and cost of equipment replacement but also ensures the stability of the production process, avoiding production interruptions caused by equipment failures.

4.The integrated structure also enables the equipment to feature a compact and small design in appearance, occupying minimal installation space. Whether in the densely arranged wiping machines in prismatic battery production lines or the limited installation areas around mechanical processing equipment, this micro-dispensing pump can be flexibly integrated without the need for major modifications to the existing production layout. It perfectly adapts to the space requirements of different scenarios, saves enterprises the time and cost of site adjustments, and further enhances the equipment's adaptability and practical value.

Guangzhou Ascend Precision Equipment Co., Ltd. has always adhered to driving product upgrades through technological innovation and optimizing solutions oriented towards customer needs.

https://www.ascendtechs.com/guangzhou-ascend-micro-dispensing-pumps-empower.html

Guangzhou Ascend Precision Machinery Co.,Ltd.