Pump seals are an essential component of many industrial processes, ensuring the safe and efficient transfer of fluids. They play a critical role in preventing leaks, reducing downtime, and maintaining the integrity of the system. In this article, we will explore the purpose of pump seals, their function, and the different types available.

What is the Purpose of the Seal on a Pump?

The primary purpose of a pump seal is to prevent the leakage of fluid from the pump. This is achieved by creating a barrier between the rotating shaft and the stationary pump housing. The seal must be able to withstand the pressure and temperature of the fluid being pumped, as well as the friction and wear caused by the rotating shaft.

Function of Pump Seals:

Pump seals work by creating a seal between the rotating shaft and the stationary pump housing. This seal is typically made up of two parts: a stationary component and a rotating component. The stationary component is attached to the pump housing, while the rotating component is attached to the shaft. As the shaft rotates, the two components come into contact, creating a seal that prevents fluid from leaking out of the pump.

Types of Pump Seals:

There are several types of pump seals available, each with its own unique features and benefits. Some of the most common types include:

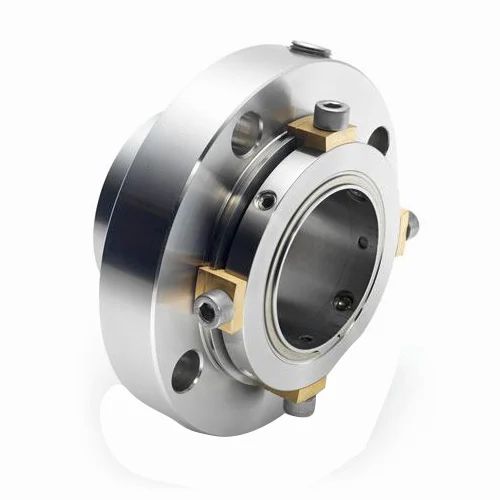

- Mechanical Seals: These seals are the most common type used in industrial pumps. They consist of two flat surfaces that are pressed together to create a seal. Mechanical seals are highly effective at preventing leaks and can withstand high pressures and temperatures.

- Lip Seals: Lip seals are used in pumps that handle low-pressure fluids. They consist of a flexible lip that creates a seal between the shaft and the housing. Lip seals are easy to install and maintain but are not suitable for high-pressure applications.

- Cartridge Seals: Cartridge seals are pre-assembled and can be easily installed without the need for special tools or equipment. They are highly effective at preventing leaks and are suitable for a wide range of applications.

Conclusion:

In conclusion, pump seals are a critical component of many industrial processes, ensuring the safe and efficient transfer of fluids. They play a vital role in preventing leaks, reducing downtime, and maintaining the integrity of the system. By understanding the purpose and function of pump seals, you can choose the right type for your application and ensure the smooth operation of your system.