In the realm of logistics and transportation, two terms often come into play: trailers and containers. While they may seem similar at first glance, there are crucial differences between the two that can significantly impact the efficiency and cost-effectiveness of supply chains. In this blog post, we will delve into the intricacies of trailers and containers, exploring their unique characteristics, applications, and advantages. By the end, you will have a comprehensive understanding of these logistics essentials.

- Definition and Structure:

Trailers: A trailer refers to a non-motorized vehicle designed to be towed by a truck or tractor. It consists of a chassis, wheels, and an enclosed or open cargo area. Trailers come in various types, including flatbeds, refrigerated trailers, dry vans, and specialized trailers for specific cargo types.

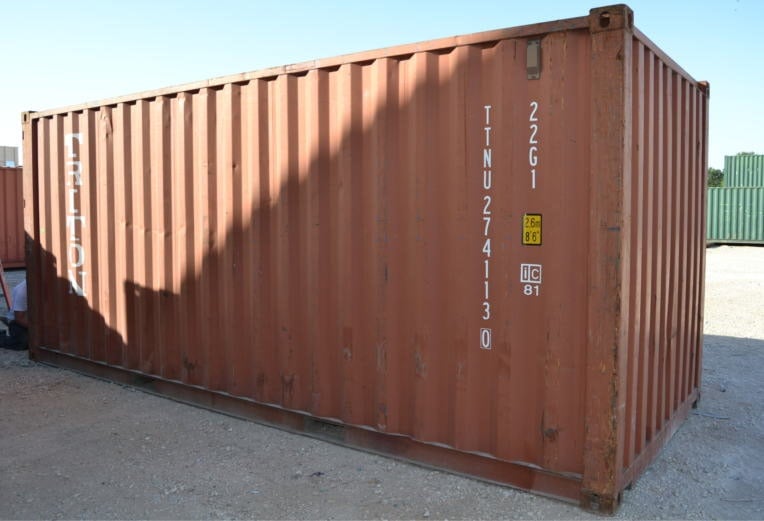

Containers: On the other hand, a container is a standardized, reusable metal box used for transporting goods internationally. These rectangular structures are built to withstand the rigors of long-distance transportation and are typically made of steel or aluminum. Containers come in different sizes, such as 20-foot, 40-foot, and 45-foot, and can be either dry or refrigerated.

- Mobility and Flexibility:

Trailers: Trailers offer greater mobility and flexibility compared to containers. They can be easily detached from the truck or tractor, allowing for efficient loading and unloading at various locations. Additionally, trailers can be maneuvered into tight spaces, making them suitable for deliveries in urban areas or construction sites.

Containers: Containers, on the other hand, are designed for intermodal transportation, meaning they can be seamlessly transferred between different modes of transport, such as ships, trains, and trucks. This standardized approach streamlines logistics operations, reducing the need for cargo handling and minimizing the risk of damage during transfers.

- Cargo Capacity and Security:

Trailers: Trailers generally have a larger cargo capacity compared to containers. They can accommodate bulky or irregularly shaped goods that may not fit within the standardized dimensions of containers. However, due to their open design, trailers may require additional security measures to protect the cargo from theft or damage.

Containers: Containers offer enhanced security for goods during transportation. Their sturdy construction and standardized locking mechanisms make them less susceptible to theft and tampering. Moreover, containers can be sealed and tracked, providing an added layer of security and traceability throughout the supply chain.

- Cost Efficiency and Environmental Impact:

Trailers: Trailers are often more cost-effective for short-haul or regional transportation. Their detachable nature allows for efficient use of trucking resources, reducing empty miles and optimizing fuel consumption. However, trailers may require additional storage space and infrastructure for loading and unloading, which can increase operational costs.

Containers: Containers excel in long-distance transportation, particularly for international trade. Their standardized dimensions enable efficient stacking and utilization of cargo space on ships, reducing shipping costs per unit. Additionally, containers can be easily transferred between different modes of transport, minimizing the environmental impact associated with cargo handling and transshipment.

Conclusion:

In summary, while both trailers and containers play vital roles in the logistics industry, they possess distinct characteristics that cater to different transportation needs. Trailers offer mobility, flexibility, and larger cargo capacity, making them suitable for regional distribution. On the other hand, containers excel in intermodal transportation, providing enhanced security, cost efficiency, and environmental sustainability for global trade. Understanding these differences empowers businesses to optimize their supply chains and choose the most suitable mode of transportation for their specific requirements.