Water pumps play a crucial role in various industries, from automotive to agriculture. When it comes to choosing the right water pump, two primary options emerge: electric and mechanical water pumps. While both serve the same purpose of circulating water, they differ significantly in terms of operation, efficiency, and maintenance. In this blog post, we will delve into the intricacies of electric and mechanical water pumps, highlighting their differences and helping you make an informed decision.

- Operation:

Electric Water Pumps:

Electric water pumps are powered by electricity and utilize an electric motor to drive the impeller. They are commonly found in modern vehicles and residential applications. These pumps offer precise control over water flow and can be easily adjusted to meet specific requirements. Additionally, they can be integrated with electronic systems for automated operation and monitoring.

Mechanical Water Pumps:

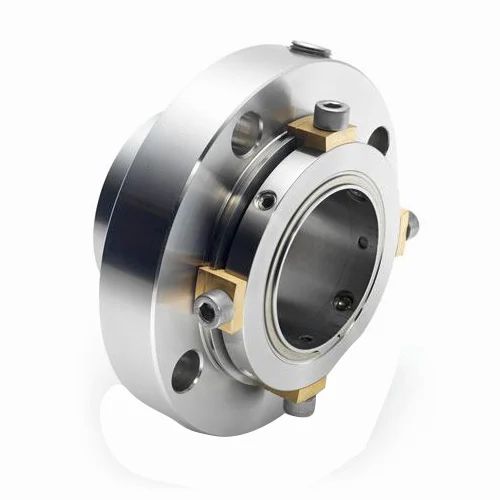

Mechanical water pumps, on the other hand, are driven by the engine's crankshaft through a belt or pulley system. They have a simple design and rely on the engine's mechanical power to circulate water. Mechanical water pumps are commonly used in older vehicles and industrial applications. While they lack the advanced features of electric pumps, they are known for their reliability and durability.

- Efficiency:

Electric Water Pumps:

Electric water pumps are known for their high efficiency. They can be precisely controlled to deliver the required amount of water, reducing energy consumption. Moreover, they do not rely on the engine's power, resulting in improved fuel efficiency. Electric water pumps also offer better cooling performance, especially in situations where the engine is not running, such as during idling or in hybrid vehicles.

Mechanical Water Pumps:

Mechanical water pumps are generally less efficient compared to their electric counterparts. Since they are directly driven by the engine, they consume a portion of the engine's power, leading to a slight decrease in overall efficiency. However, mechanical water pumps are still widely used in heavy-duty applications due to their robustness and ability to handle high temperatures and pressures.

- Maintenance:

Electric Water Pumps:

Electric water pumps require minimal maintenance. They do not have any mechanical components prone to wear and tear, such as belts or pulleys. However, periodic inspection and testing of electrical connections and motor performance are recommended to ensure optimal operation. In case of any malfunction, the entire unit may need to be replaced, which can be more expensive compared to repairing mechanical pumps.

Mechanical Water Pumps:

Mechanical water pumps require regular maintenance to ensure their longevity. The belts or pulleys driving the pump need to be inspected and replaced periodically. Additionally, the pump's bearings and seals may require lubrication or replacement over time. While maintenance is more involved, the individual components of mechanical water pumps can be repaired or replaced, making them more cost-effective in the long run.

Conclusion:

In summary, electric and mechanical water pumps differ in terms of operation, efficiency, and maintenance. Electric water pumps offer precise control, high efficiency, and low maintenance requirements, making them ideal for modern vehicles and residential applications. On the other hand, mechanical water pumps are known for their reliability, durability, and ability to handle heavy-duty tasks. Understanding these differences will help you choose the right water pump for your specific needs, ensuring optimal performance and longevity.